A TIMELY DELIVERY TO THE DOT

Food Processing Plant for JRS India Corp Pvt Ltd., Ahmedabad

It was all a matter of dates for Project Manager, Hemant Gupta and his B&F IC team at the JRS (India) Food Factory project in Ahmedabad.

“These dates were cast in stone with absolutely no scope for negotiations even as the design was continuously evolving and our scope increasing with new additions,” recalls Hemant, the memories creating worry lines on his forehead. The client, M/s J R Simplot, was entering India to set up a special process plant with a 6 ton/hour capacity for the initial line, and as their EPC partner, L&T was expected to deliver as per the contractual stipulations. “Being on an EPC model, we had to coordinate with several OEMs across five countries and lack of closure on design and scope was not helping us,” adds Hemant.

One can understand Planning Manager, Vinoth Kumar’s headache in this situation. “All the international vendors onboarded for commissioning the process plant line were scheduled as per the original dates and prebooked 9 months in advance, so it was hugely challenging to keep their trust intact and live up to the client’s faith in L&T.”

Tough situations warrant new solutions

One of the team’s initial challenges pertained to coordinating with multiple process equipment vendors across different regions and overcoming language barriers to ensure smooth design integration. “By leveraging structured communication templates, multilingual documentation, and collaborative digital platforms like BIM 360, we met the expectations of all our stakeholders including in design, execution and delivery,” shares a delighted Design Manager, Magesh Kumar.

Setting up the MEP Systems was another tall order having to adhere to stringent global food hygiene standards, incorporating first-of-their-kind systems like GFS (Glass Fused Steel) tanks, Zero Liquid Discharge Systems, Glycol-based process cooling systems, cold storage refrigeration and associated MEP systems apart from integrating the MEP system with the process equipment, many of which were being deployed in B&F IC for the first time. “By leveraging our inhouse design expertise residing within the EDRC design team, we were able to successfully deliver the project on time,” Magesh’s smile says it all.

Procurement Manager, Vinod Pandey’s challenge was to get Customs to clear some 400-odd sea containers full of equipment & machines arriving in knocked down condition on time. “Thanks to the Just In Time concept, we were able to directly position the equipment on to the foundations that eliminated rehandling costs,” he grins.

It is often said that a team that eats together, stays together, and one of the unique yet simple initiatives that Hemant introduced was to have lunch with all the department heads. “In that one hour over lunch, we were able to catch up on how things were progressing in each building from morning to lunch and during the course of the discussions, we got to hear stories and accounts of what was happening at ground zero that put everyone on the same page.” Hemant stops for a moment, perhaps reliving some of those war stories shared at the table. “It really worked wonders,” he resumes with gusto, “and we achieved a high degree of synergy between the teams.”

He shares another of his peoples’ initiatives that he calls “Prep’ involving all the stakeholders right up to the Foreman level, for all to understand how one particular agency would be working that reduced reworks to almost nothing. Hemant and team extended this exercise even to the trial phase by initiating morning huddles involving the client, the OEM engineers, and his team to promptly resolve day-to-day issues. In fact, they endeavoured to close issues in less than 24 hours that contributed significantly to their successful and timely delivery of the project.

Project features

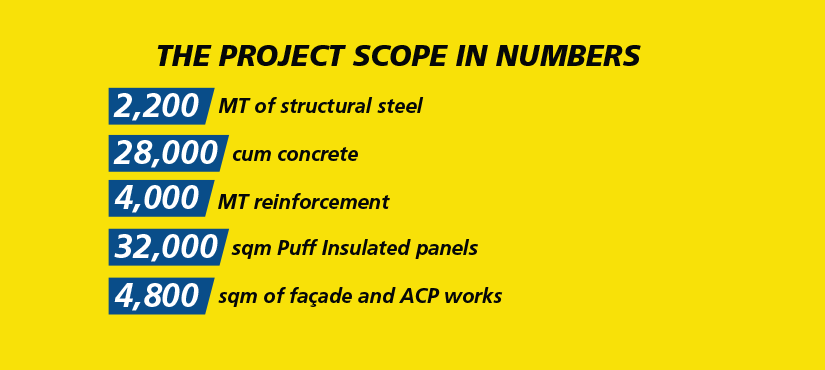

A few highlights of the project included specialized mechanical utilities consisting of ammonia, compressors, boilers, AHU units, cooling towers, Gycol systems, fire protection & fire alarm systems, VESDA system, IT networks, CCTV and access control systems, and more. Civil structures included a PEB building, hygiene rooms, a cold storage warehouse, an administrative building, security facilities complete with interior finishing, furniture and a transit house with interiors & furnishings. Utilities included a 66 kV switch yard, a control building, a 11 kV transformer yard, among others. External development involved a security compound wall, ponds, landscaping, trees, hardscaping, shrubs & hedges, recharge well system, and traffic signage.

A well thought through delay mitigation strategy

An extremely insightful step taken by the team was to liaise with the IBR Inspector right from conceptualization to final certification that was beyond the scope of the original contract. “Our proactive consideration of Natural Gas skid with provision of a gas flow meter saved us approximately 4-5 months,” mentions a happy Vinoth, “for reduced gas connection requirements led to GSPL to Gujarat Gas.” The team’s initiative to procure and instal cable trays from Vandenpole that falls in the OEM’s scope further mitigated delays and even though the contract stipulated a non-walkable false ceiling, the team designed and installed a serviceable false ceiling for easier maintenance in future.

Tackling speed with safety

Even as the team pressed the pedal to deliver as per the committed dates, the onus on EHS Head, Chirag Soni, was to ensure that the highest Safety standards were met and sustained, and lives kept safe. “The proof that we prioritized Safety above everything else is reflected in our clean EHS record of no fatalities or LTI and the fact that we won British Safety Council’s Sword of Honour,” he says with a thumbs up.

Technology, another key contributor to success

Apart from having a BIM studio at site that was not part of the contract, Hemant used BIM slightly differently to his and the project’s advantage. “As Project Manager, I decided to share the sequence of services in BIM to all right up to Foreman level,” shares Hemant, “which is a little unique for normally engineers only check BIM to see the route and sequence. My initiative helped in reducing reworks and abortive works to a very large extent,” he smiles with great satisfaction.

A measure of the client’s trust in the team’s capability was that they did not have any consultants or third parties at site to monitor progress. “The onus of delivering to quality, safety and time was entirely on us and it is a great feeling that we were able to live up their expectations and deliver a project that we are all extremely proud off,” rounds off Hemant, triumphantly.