Chennai Metro Rail Limited (CMRL)

Phase 2, Corridors 3 & 5 – PS06 Package

Leveraging BIM360 with a federated strategy

As the citizens of Chennai eagerly await the second phase of the city’s Metro, Project Manager Alphonse A & team are hard at work to power it. PT&D IC is executing the design, manufacturing, supply, installation, testing & commissioning of the receiving substation (RSS), auxiliary substation (ASS) equipment, earthing & cable routing, OCC room SCADA, and viaduct cable routing – including three 110 kV RSS and 54 ASS substations.

The architecture, structure, and equipment BIM models have been developed by the team based on the latest civil and electrical design inputs. “BIM360 enhances collaboration, efficiency, and project outcomes, and by leveraging Autodesk’s cloud- based platform, we have achieved seamless collaboration, real-time data access, and enhanced project coordination across all disciplines,” highlights Alphonse.

“Digital technologies like 3D & 4D BIM, VR, & AR can coalesce to generate business value and improve competitiveness, giving us an edge in the marketplace,” comments Geetha Hariharan, Head – Engineering (SAARC Nations), who has been leading the BIM efforts at PT&D.

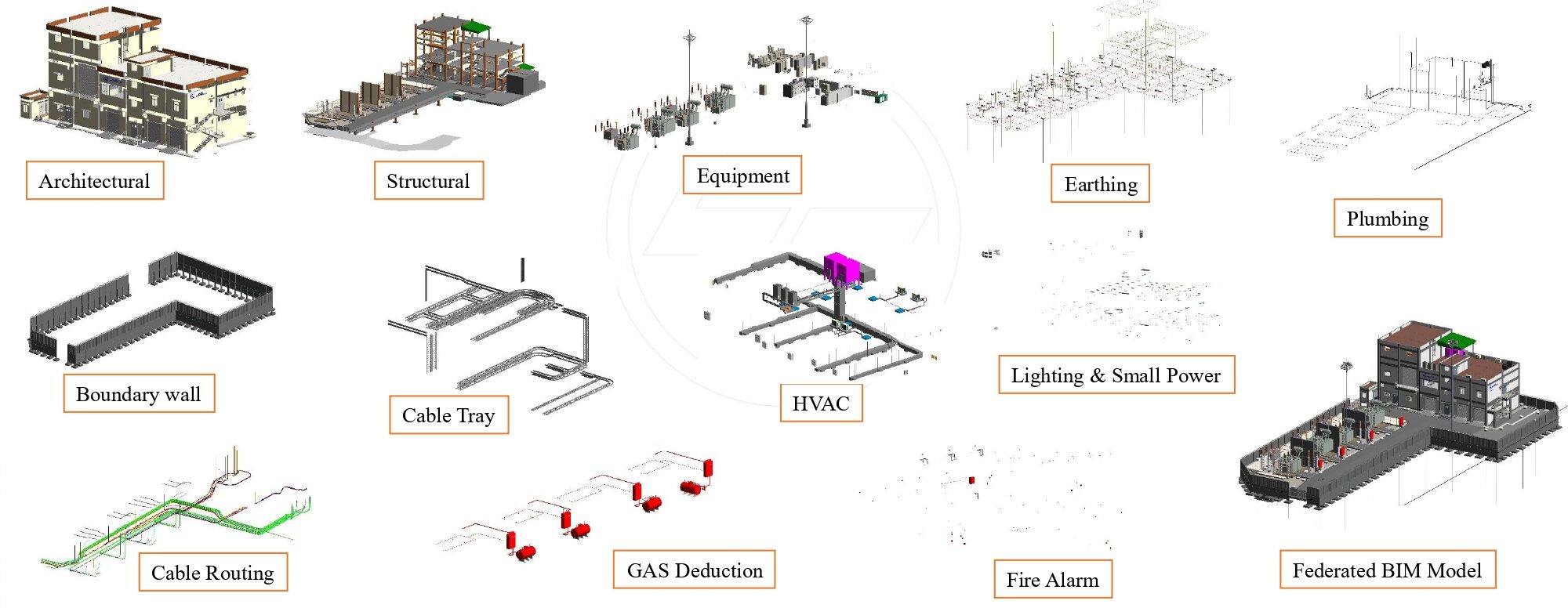

The project team has undertaken a federated strategy to author the 3D BIM design, in coordination with various discipline models like civil, equipment, HVAC, firefighting, lighting, and others. The ASS inputs interface with various contractors in other packages of the Metro – DPT02, UG01, UG02, UG03, UG04, UG05, UG06, EV01, & EV03 – all of which have been incorporated into the BIM model, collaborated through the Autodesk Construction Cloud (ACC) platform. The HVAC model has been developed from the HVAC flow diagram and cubic feet per minute (CFM) airflow calculations.

Stringent approval processes, rigid work methodologies, and the client’s requirement of the consultant witnessing 100% of the work were some of the significant operational challenges the team faced during execution. While the BIM360 measures were implemented to ensure quality assurance and regulatory compliance, they have positively impacted schedule adherence, workflow efficiency, and resource planning.

“Automation has reduced model creation time from 1,200 to approximately 900 manhours,” informs Geetha, “and BIM has given us a much-improved level of accuracy in estimating the bill of materials for LOT items, as it is directly extracted from the 3D models.”

A three-dimensional client walkthrough

Cable trays and light fixtures placed at their respective locations in the BIM 3D model are regularly updated as per latest inputs from review meetings. Fire & gas detection and inert gas systems can also be incorporated into the model from the vendors’ inputs.

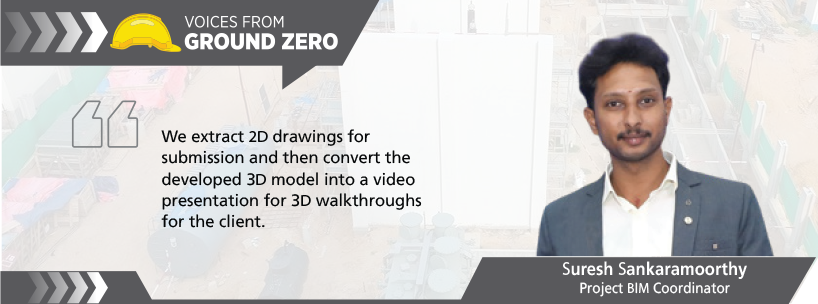

Engineers from all disciplines perform checks on a weekly basis and arrive at resolutions to avoid system clashes. “We extract 2D drawings for submission and then convert the developed 3D model into a video presentation for 3D walkthroughs for the client,” reveals Suresh Sankaramoorthy, Project BIM Coordinator, who adds smilingly that this ploy has helped them obtain quicker approvals, have helped in reviews too. The client reviews the project progress using the 4D construction sequence & simulation linked to the project’s L4 schedule. At the end of the day, the 3D BIM model has eliminated clashes, errors, and rework.

“By leveraging 4D modelling to link construction activities with our project schedule, we plan better, detect clashes, and execute on time,” Alphonse notes, “and by integrating BIM 5D, we are tracking real-time cost impacts alongside design changes, helping us maintain budget control and improve financial forecasting.”

Enhancing collaboration through BIM

With tools like Revit, Navisworks, and ACC, Suresh & team perform stringent weekly quality checks that include geometric & visual accuracy, standards compliance, and LOD compliance. “All technicians and discipline BIM leads are responsible to perform these checks, one of the most important being model integrity checks to ensure that elements are modelled correctly spatially and associated to the relevant reference grids & levels,” explains Alphonse. This crucial step avoids duplication of elements & overlapping and ensures that no objects are missed.

The federated 3D model for the Madhavaram RSS Substation was prepared in coordination with various discipline models like civil, equipment, HVAC, firefighting, lighting, etc.

Document and interface management is through Autodesk BIM Collaborate Pro for common data storage and easy design collaboration among multiple stakeholders, across the different packages. This centralized system allows all stakeholders to access the latest project files, drawings, and specifications, streamlining construction workflows such as RFIs, checklists, quality inspections, and issue tracking. “With this real-time data sharing and markup, our decision-making and issue resolutions are quicker” notes a pleased Geetha. “All updates are tracked, logged, and accessible through the cloud, reducing disputes and miscommunication.”

The successful implementation of BIM360 in PT&D’s CMRL project demonstrates the tangible benefits of digital construction management. By breaking down communication barriers and enabling data-driven decisions, BIM360 has empowered the project team to deliver a higher-quality build with greater efficiency. “With improved productivity thanks to faster data collection and fewer revisions in the engineering document submissions, we have realized cost savings too. We are confident of meeting the contractual end date of September 2027, quite comfortably,” remarks Alphonse with a grin as he signs off.

765 kV Mandsaur–Indore and

Mandsaur–Rishabdeo Transmission Corridors

Smart transmission line planning using LiDAR

For decades, planning of transmission lines relied heavily on differential GPS (DGPS)–based survey methods. While effective for their time, these methods are labour-intensive, timeconsuming, and often fragmented. Detailed topographical and check surveys for large-scale transmission projects typically take 5–6 months, delaying project initiation and increasing resource strain. Moreover, route alignment and tower spotting – the activity of determining the optimal locations for transmission towers along a power line route – required multiple site visits to validate terrain data, resulting in inefficiencies and limited accuracy. This iterative process created roadblocks in earlystage decision-making, procurement planning, and overall project timelines.

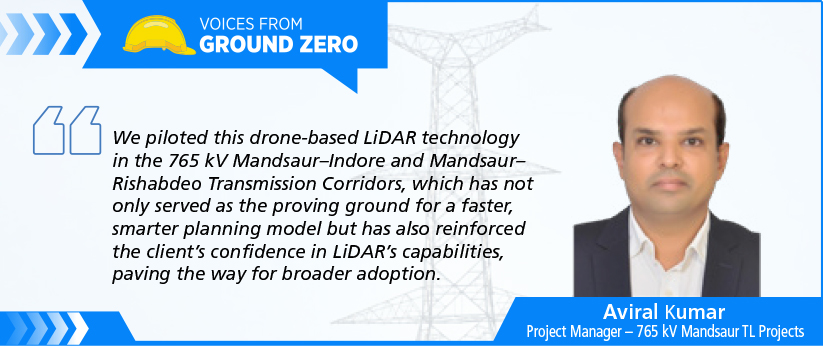

“To address these challenges, we adopted drone-based aerial Light Detection and Ranging (LiDAR) technology for high speed, high-accuracy data collection from the air,”reveals Aviral Kumar, Project Manager of the 765 kV Mandsaur TL Projects. “LiDAR captures high-resolution 3D spatial data and HD-quality terrain imagery, offering unmatched visibility into land contours, vegetation, and ground conditions.” His engineering teams were better equipped to generate more reliable alignment profiles and make informed decisions at an early stage. “With LiDAR, teams perform route alignment and tower spotting remotely – right from their desks, reducing field visits, with the added benefits of precision, speed, and efficiency,” adds Aviral.

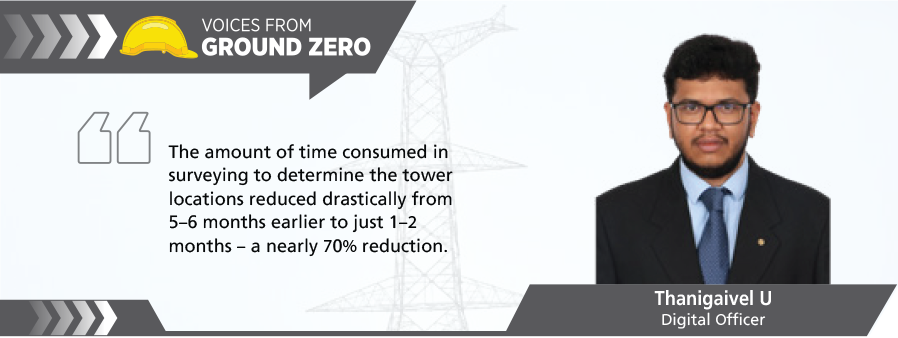

- Time savings: “The amount of time consumed in surveying to determine the tower locations reduced drastically from 5–6 months earlier to just 1–2 months – a nearly 70% reduction,” notes Thanigaivel U, Digital Officer, with a note of satisfaction.

- One-time data collection: LiDAR provides a comprehensive single-shot dataset, eliminating the need for piecemeal data gathering.

- Improved accuracy: High-resolution terrain models ensure precise route alignment and tower spotting, reducing redesign cycles.

- Faster procurement and logistics: With early clarity on tower types and locations, material planning and resource allocation can begin earlier, leading to fewer delays and lower costs.

“We piloted this drone-based LiDAR technology in the 765kV Mandsaur–Indore and Mandsaur–Rishabdeo Transmission Corridors,” states Aviral, “which has not only served as the proving ground for a faster, smarter planning model but has also reinforced the client’s confidence in LiDAR’s capabilities, paving the way for broader adoption.” With LiDAR, the future looks bright for tower spotting in transmission line projects!

In transmission line projects, the tower configuration refers to the tower’s overall appearance or geometry and the spatial arrangement of the conductors. Once the tower configuration is established, the tower design process begins, which is technical and closely follows specific technical specifications and international standards.

Electrical clearance, which refers to the minimum distance required between live conductors and the tower body, the ground, or any other object, significantly influences tower configuration, while the tower foundation design involves securely anchoring the tower to the ground to ensure stability and reliability. “Like residential building construction, the forces from the tower structure affect foundation design and, ultimately, the overall cost,” explains Thanigaivel.

Traditionally, the focus is to optimize the tower design first by reducing the tower weight as much as possible, before designing & optimizing the foundation. This way, though the tower and foundation designs are optimized, it is unclear whether the combined cost of tower and foundation is at the minimum. Moreover, the multiple tower and foundation geometries typically demand substantial time and resources.

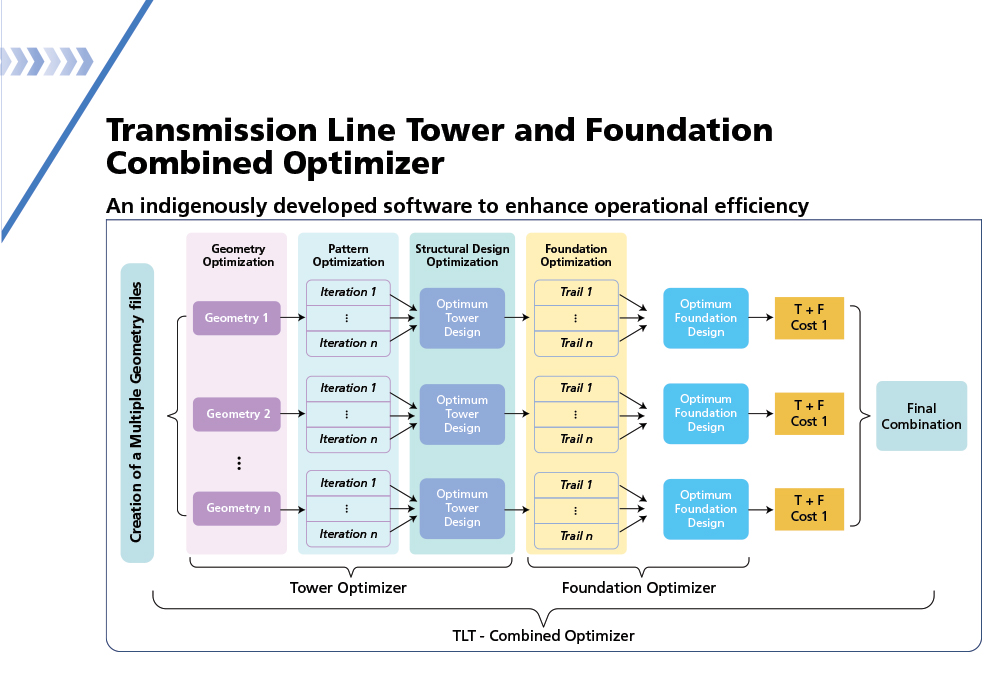

So, what’s the solution? PT&D’s Transmission Line (TL) division, teaming up with EDRC, has pioneered a cutting-edge tool: the Transmission Line Tower and Foundation Combined Optimizer, or TLT-COP, to design and optimize hundreds of tower and foundation configurations and then identify the most cost-effective option. “By automating the comprehensive optimization of all these interconnected elements, TLT- COP aims to deliver the best result,” notes Rajiv Ranjan, Head – Engineering (TL). “Specifically designed to improve production efficiency and reduce time & resources, the tool is an innovative solution amid an increasingly competitive market landscape.”

“To streamline and accelerate this optimization process, we have established an interoperable software ecosystem,” says Karthick Ganapathy, Lead Engineering Manager (Civil), “that seamlessly exchanges data between the existing tower design software (TLT Soft – an inhouse-developed software for tower design) and the newly developed foundation optimizer.”

A robotic process automation (RPA) tool integrates these systems, ensuring that all software components operate cohesively as a unified platform that optimizes cost by refining the geometry of the tower for maximum efficiency. “Automation significantly shortens the time required for the design and analysis of various tower and foundation combinations, providing a significant edge during the tendering stage for bidding,” remarks Rajiv.

“To initiate the optimization process, the user inputs the minimum & maximum range of fundamental dimensions for both the tower and the foundation, along with key data such as material costs and soil properties,” elaborates Karthick. “In the simulation process, the system automatically analyses and designs the TL tower and foundation through power automation using Python code, TLT, and STAAD.pro software, which involves the optimization of geometry, configurations, structural design, and foundation through a trial-and-error approach.”

This tool has been used in the 765 kV Navasari–Padghe TL, Gujarat, and 800 kV HVDC Bipole KPS2 to Nagpur TL projects, where the teams have reaped the benefits of increased productivity, improved quality & cost sensitivity, accurate & optimal solutions, and speedier results. Karthick is a happy man, for by reducing manual intervention with the option of making real-time adjustments, the TLT-COP has significantly enhanced the team’s production efficiency. “The automated workflow, combined with continuous process monitoring, has given us better performance and overall product quality, precise analysis, and consistent delivery of optimal design solutions,” he adds.

“We are seeing the benefits of the TLT-COP tool during the tendering stage as well, and soon, we plan for this initiative to involve international calculations in the foundation optimizer, raft and pile foundations and automated sub-bracing pattern selection,” Rajiv informs, looking ahead.