Simple yet powerful innovations

The B&F Prestige Palm Grove project in Bengaluru is no exception. During routine reviews, the project team saw an opportunity to make window protection systems even safer. Their solution: the addition of a third handrail for larger window openings that has set a new benchmark, offering extra security beyond conventional safety standards. “Taking this further, we have introduced portable and adaptable window protection gates, designed to move seamlessly with the pace of work and protect the finishing at every stage,” elaborates G Suresh, Project Director, Prestige Park Grove Project, which involves the construction of 19 towers and 88 villas.

Additional railings deployed for large windows

![]()

We have introduced portable and adaptable window protection gates, designed to move seamlessly with the pace of work and protect the finishing at every stage.

G Suresh

Project Director,

Prestige Park Grove Project

![]()

Tackling safety during material handling and work-at-height operations have become progressively better. While previously scaffoldings were extensively used for high-access tasks, these days there is an increasing use of Mobile Elevating Work Platforms (MEWPs), as Kouser Ahmed, Project Manager, Toyota Kirloskar Motors Ltd Project, Bidadi, points out. “Traditionally deployed for structural steel erections and façade installations, MEWPs are now being used even for de-slinging loads during unloading operations, providing workmen with a stable and secure platform to perform tasks safely.” Mentioning that there are more than 80 MEWPs in use simultaneously at his project under robust control frameworks, Kouser agrees that the introduction of MEWPs has been a welcome shift towards safer, more efficient, and more controlled work environments.

Improvements in traffic management have been in the form of providing overhead protection along pedestrian routes, particularly near active building zones in addition to dedicated pedestrian pathways for personnel to move safely amidst construction activities, equipment operations, and work-atheight activities, thereby minimizing exposure to potential hazards.

Large-scale transitioning from scaffolds to MEWPs

![]()

Traditionally deployed for structural steel erections and façade installations, MEWPs are now being used even for de-slinging loads during unloading operations, providing workmen with a stable and secure platform to perform tasks safely.

Kouser Ahmed

Project Manager, Toyota Kirloskar Motors Ltd Project, Bidadi

![]()

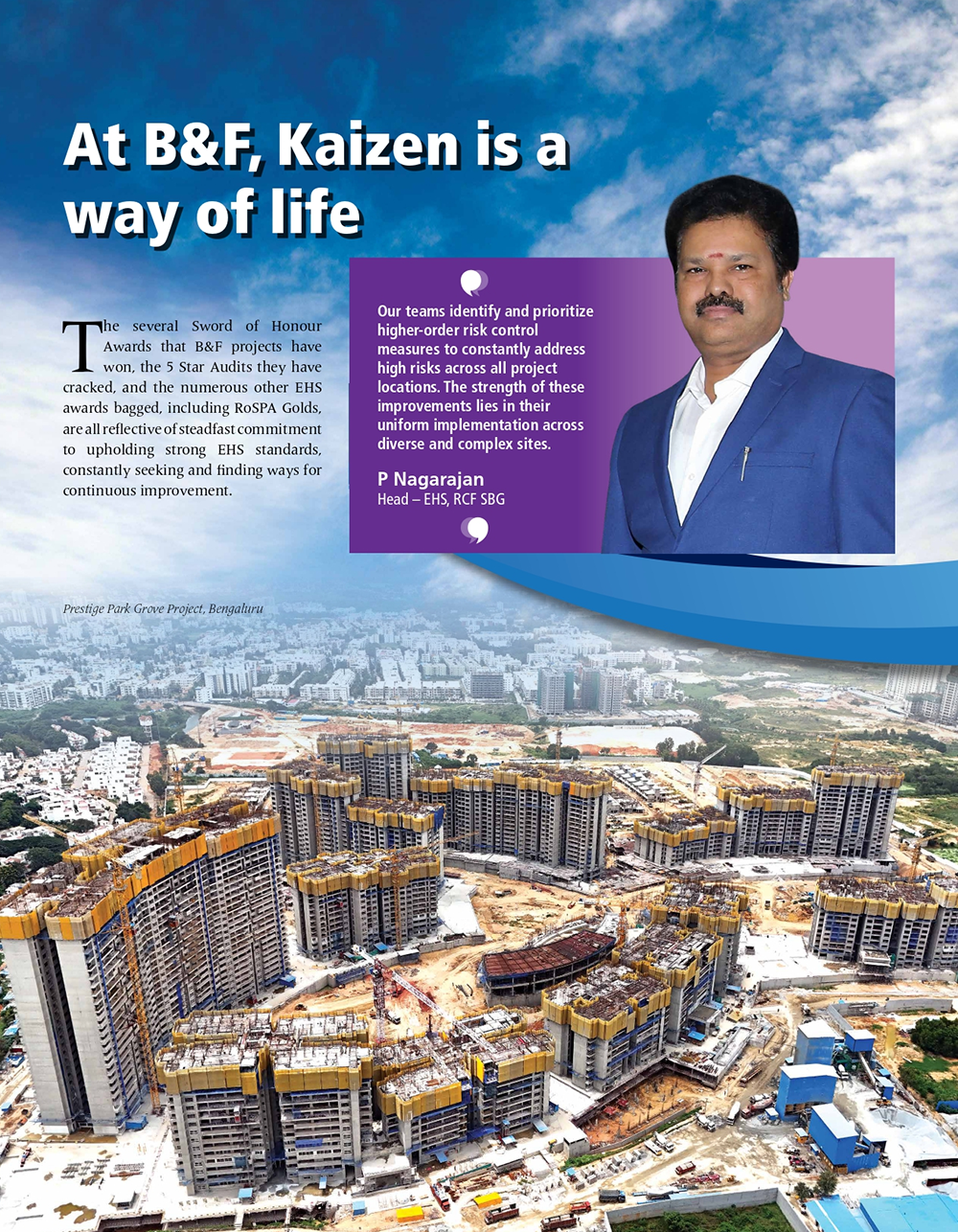

Each of these initiatives stems from a structured risk profiling process carried out at the site level. “Our teams identify and prioritize higher-order risk control measures to constantly address high risks across all project locations,” nods P Nagarajan, Head – EHS RCF SBG. “The strength of these improvements lies in their uniform implementation across diverse and complex sites.” He is glad that their efforts to drive EHS are consistently and solidly supported by the senior leadership. “More than just endorsing them, our senior leaders drive EHS performance by taking active hands-on roles in strategizing control measures, reviewing risk assessments, allocating resources, and tracking implementation. They help turn intent into impactful action,” he avers.

Visible and engaged leadership has transformed the EHS practice from a set of procedures into a core organizational value, woven into every operational decision. “It is this leadership-driven culture that ensures that safety is not just practised but lived at our sites and facilities, every single day,” sums up Nagarajan resolutely.