Preserving heritage above,

to drive development below

Mumbai Metro (Aqua Line) Line 3 (MMRC – 01)

October 8th, 2025, was yet another red-letter day for L&T as Prime Minister Shri. Narendra Modi inaugurated the final phase of the 33.5 km Aqua Line, the first fully underground corridor of the Mumbai Metro connecting Colaba in South Mumbai to SEEPZ. Even as Heavy Civil Infrastructure IC’s project team led by Project Manager, Shripad Sudhakar Ghate, celebrate their achievement, they cannot forget the deep challenges they had to overcome to construct the Hutatma Chowk Station involving a 255 m long, 9.7 m high, & 11.78 m wide platform tunnel using the New Austrian Tunnelling Method (NATM), with century-old heritage structures, valued for their architectural and historical significance, crouched above separated by just 3 m of rock.

![]()

We were given not just a project to execute but an opportunity to safeguard history and, at the same time, ensure urban progress, and we have succeeded on both fronts.

Shripad Sudhakar Ghate

Project Manager

![]()

Preserving heritage

Constrained by a narrow but prominent road, the team had to contend with fragile & shallow foundations of the heritage buildings that were showing noticeable deterioration, combined with a shallow cover of approximately 16 m inaddition to proximity to the station retention system. The tough Deccan Trap geology compounded their challenges, characterized by hard basaltic rock mass with Uniaxial Compressive Strength (UCS) ranging from 50 to 125 MPa, which called for extremely controlled blasting.

“Towards preserving the heritage structures above, we carried out rigorous pre-construction assessments & structural audits, adopted building protection methods, and continuously monitored progress throughout the construction period,” shares Shripad, for whom the construction process was hindered by several roadblocks including a controversy over tree-cutting that threatened to throw his schedule out of kilt and, more annoyingly, keep his TBM idling for long.

A detailed building condition survey kicked off their efforts to ascertain the existing physical condition of the heritage buildings, which involved a comprehensive visual inspection of both exterior and interior elements. “Understanding the structural integrity of these buildings was critical,” highlights B Prannoy, Construction Manager (Civil), “which involved identifying cracks, deformation, signs of structural damage, and the extent of material degradation by examining the spalling of concrete, rusting of steel, and general wear & tear.”

Structural audits followed to determine the overall stability of the structures using non-destructive testing methods and physically & chemically testing the concrete to assess the condition of critical structural elements like walls, columns, and beams. “We were then able to estimate the residual strength of the materials and structural elements, identify the areas that required immediate strengthening or repair, and provide recommendations to stabilize the buildings during excavation if required,” explains Shripad. The audit results formed the basis for the team to develop tailored mitigation and protection plans for each building. For an even deeper understanding, the team excavated trial pits near critical structural elements like columns, seeking insights into the foundation depth, materials, and damage.

“We designed & installed customized structural steel supports to reinforce the arches and prevent damage from the vibrations or ground movement, which both distributed loads and minimized stress on the arches,” informs R Sudharsan, Senior Deputy General Manager – EHS, HCI IC. Apart from temporary coverings and supports to safeguard delicate ornamental features, vulnerable beams and slabs were given extra supports.

![]()

Understanding the structural integrity of these buildings was critical, which involved identifying cracks, deformation, signs of structural damage, and the extent of material degradation.

B Prannoy

Construction Manager (Civil)

![]()

Technology lends a helping hand

Shripad mentions installing geophone sensors in the buildings to monitor blastinduced ground vibrations in terms of Peak Particle Velocity (PPV), carefully optimizing the Maximum Charge per Delay (MCD) to 2.54 mm/sec, which was well within the permissible limit of 5 mm/sec specified in the contract for heritage structures. Additionally, tilt sensors continuously recorded angular displacements in buildings, detecting even minute shifts. “Our automated robotic total station, accessible to all stakeholders, accurately tracked 3D movements of heritage buildings,” he elaborates, “and with this real-time data, we could compare the actual movements with predicted thresholds, for early detection of any deviations.”

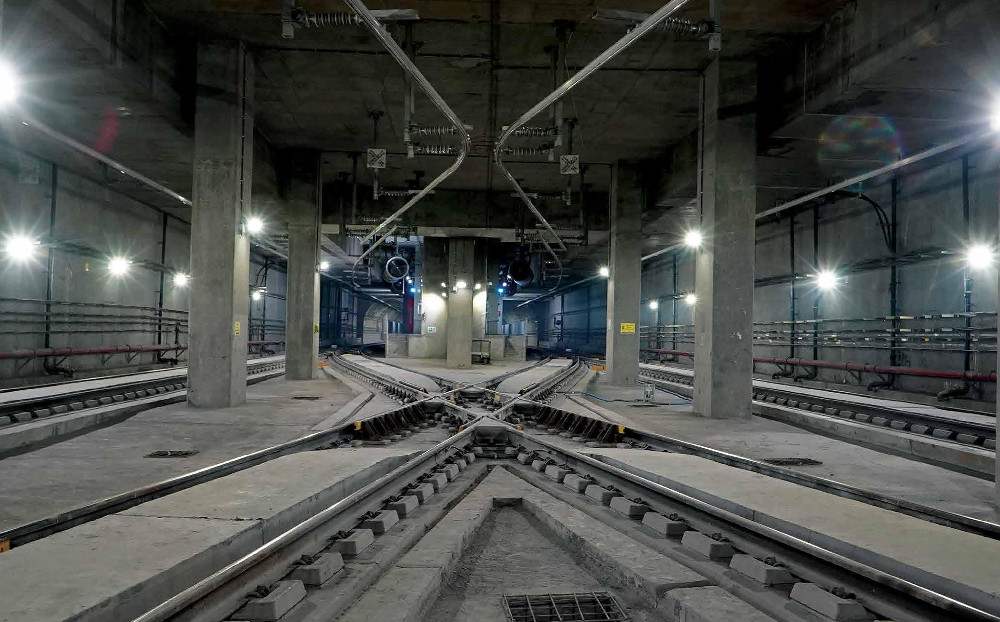

Cuff Parade crossover

![]()

Data didn’t just inform; it commanded and guided our overall planning, operations, and execution.

Swapnil Avinash Patil

EHS Head

![]()

For Swapnil Avinash Patil, EHS Head, the 25 million safe manhours clocked by the UGC-01 project without any LTI is a matter of immense pride. “Excavation was paused if we detected even a small anomaly,” he says. “Data didn’t just inform; it commanded and guided our overall planning, operations, and execution.”

Blasting with care

While the team had to be ultra-cautious about what lie above their heads, blasting in the hard basaltic terrain of the Deccan Traps was challenging, demanding that they follow a tunnel excavation sequence focused on minimizing ground vibrations during excavation. “We executed specially designed, site-specific micro blasts limiting the number of blast holes per round to between 8 and 12, to ensure minimal vibration levels,” affirms Swapnil.

A double line of peripheral dummy holes along the tunnel periphery further helped to contain vibrations, and instead of relying solely on blasting, the team used drum cutters to excavate the ground at the tunnel periphery to further restrict blast-induced ground vibrations.

Outcomes speak louder than blueprints

Shripad, Swapnil, and team have a lot to write home about, carrying on the legacy left by some of the project’s distinguished erstwhile leaders like Project Director, Aloke Kumar Dey, Project Manager, Palwinder Singh, and EHS Head, Mohsin Anwer. “Perhaps our most satisfying achievement is the validation of all our efforts through independent structural audits confirming that the heritage buildings had suffered zero damage,” notes Swapnil with a proud smile.

Scoring over 70% in the MARS audit, the highest among all the 7 packages, was another feather in their cap. “Both the tunnels we bore under Churchgate and Hutatma Chowk were LTI-free, and our EHS performance has been recognized by organizations like RoSPA, BSC, OSHAI and CII with several awards,” exults Shripad. “We were given not just a project to execute but an opportunity to safeguard history and, at the same time, ensure urban progress, and we have succeeded on both fronts,” he sums up rousingly.