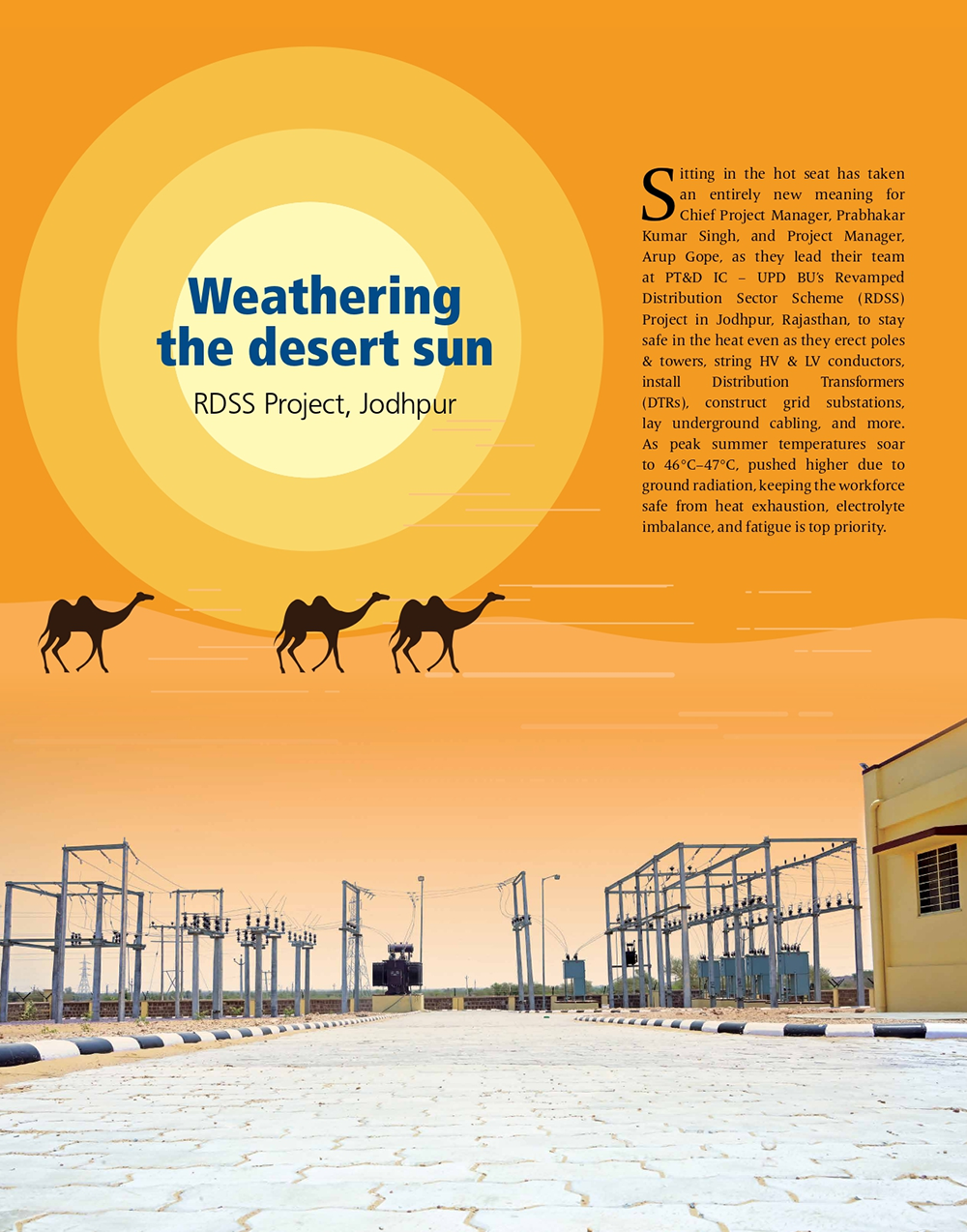

Beating the heat

“Our approach to protect our people is not just a collection of separately taken actions but an integrated strategy involving infrastructure, awareness, and accountability,” points out Prabhakar, who along with Arup and Ashim Sadhak, EHSO, is focused on beating the heat to push the project forward.

Hydration first: Being exposed to the blistering sun for long periods of time necessitates continuous hydration with clean drinking water readily available in strategically placed water campers in all workplaces, with instructions to keep taking at least 250–300 ml of water every 20–30 minutes. Apart from consuming ORS sachets, they are urged to take chaas (buttermilk) and fresh fruit juices that are rich in minerals and natural electrolytes. The prescribed diet includes light, easily digestible foods rich in fibre like fruits, vegetables, and whole grains that help digestion and keep them hydrated & energized all day long.

Protection and training: Umbrellas and cotton towels give the workers some respite from direct solar radiation.

“We periodically educate and sensitize them about the importance of early detection of heat stress symptoms, the discipline of staying hydrated, and following safe work-rest schedules,” informs Ashim. “We have ingrained compliance and vigilance into our supervisors. In fact, it is a part of our culture,” he adds with a determined look.

![]()

Our approach to protect our people is not just a collection of separately taken actions but an integrated strategy involving infrastructure, awareness, and accountability.

Prabhakar Kumar Singh

Chief Project Manager

![]()

33 kV overhead line

When the going gets tough, training saves the day, as Site Engineer, Chinmoy Banerjee, found out on site at Phalodi when a lineman started experiencing dizziness and muscle cramps due to the heat. “Knowing what to do in such a situation, we immediately swung into action, moving him into the shade and giving him ORS & water to recover,” he shares. “Our quick action not only saved the lineman’s life but also made us acutely aware of the importance of heat safety. I feel safer working here,” he grins in relief.

![]()

With a lot of planning, awareness, and disciplined implementation, the RDSS Jodhpur Project has developed a strong and proactive safety mechanism that can withstand even the toughest of circumstances that Rajasthan’s desert landscape can offer.

Arup Gope

Project Manager

![]()

Beating the heat with an insulated water camper

63 kVA pole mounted distribution substation

SHEILD protects

Arup is impressed by his team’s focus on safety, having identified, captured, and rectified 19,041 unsafe observations apart from executing 14,656 non-LC and 753 LC activities, all on the SHEILD App. “We have evaluated 2,819 nearmiss cases to know the common risks and take precautionary measures to make ours a safer, more controlled workplace,” notes Arup. With hazardous activities like pole erection, stringing, and DTR installation being monitored on SHEILD through checklists, Ashim and team ensure that every step is taken with safety on top of mind. “All activities are in accordance with the recommended safety requirements and all control measures checked prior to implementation. This uniformity at our various sites has been very important in maintaining consistent EHS compliance over a long stretch of operational coverage,” he says with a knowing nod.

In addition to conducting 2,360 VR training sessions for the workers to improve hazard awareness, all newly inducted workers undergo the vertigo test to be certified fit for work at height.

Having an ERP pays rich dividends

The team’s ERP, or Emergency Response Plan, is designed for quick, wellplanned, and effective response to emergencies, which is critical to protect men, material, & machinery in a project that is being executed in India’s sixthlargest district covering an area of 22,850 sq. km. Anchored on the principles of life, property, and environmental conservation to address any form of emergency including fire, electrical hazard, medical emergency, or external threat, the ERP ensures speedy resource mobilization and effective interaction between project teams.

“Our ERP avoids escalation and ensures that normal operations of the site are restored as soon as possible with minimum productivity loss,” states Prabhakar, who along with Arup, Ashim, and core site representatives like section in-charges, engineers, administrative staff, and store personnel form the Emergency Response Committee (ERC). To maintain preparedness, regular mock drills, toolbox talks, and awareness programmes are carried out at different work fronts to make all the workers conversant with emergency procedures.

Erection of double pole structure for 11 kV overhead line

Safety above all: Vertigo test for height fitters

ERP scores during Operation Sindoor

Situated just 120 km from the international border, the project site experienced an acute emergency during Operation Sindoor with continuous shell firing and blackouts. An Emergency Response Team, comprising Prabhakar, Arup, Ashim, Segment Head – Debashish Mukherjee, Cluster Accounts Manager – Tapas Sen, Section In-Charge – Afzal Siddiqui, and Project Accountant – Samarjeet Kumar Singh, successfully executed a rescue and relocation operation. “By coordinating with all our team members and workers, we evacuated and relocated all of them safely at Jodhpur,” apprises a proud Prabhakar. “Even in the middle of the blackout, we provided emergency light, water, food, and medical kits and ensured the supply and storage of essential items like rations, water, and medicines with power backup and emergency vehicles always ready.” After the emergency, the entire team was brought back to site equally smoothly and efficiently.

![]()

All activities are in accordance with the recommended safety requirements and all control measures checked prior to implementation. This uniformity at our various sites has been very important in maintaining consistent EHS compliance over a long stretch of operational coverage.

Ashim Sadhak

EHSO

![]()

Prabhakar, Arup, and Ashim attribute their success to converting their emergency management into a proactive process rather than a reactive one. “With a lot of planning, awareness, and disciplined implementation, the RDSS Jodhpur Project has developed a strong and proactive safety mechanism that can withstand even the toughest of circumstances that Rajasthan’s desert landscape can offer,” signs off a confident Arup.