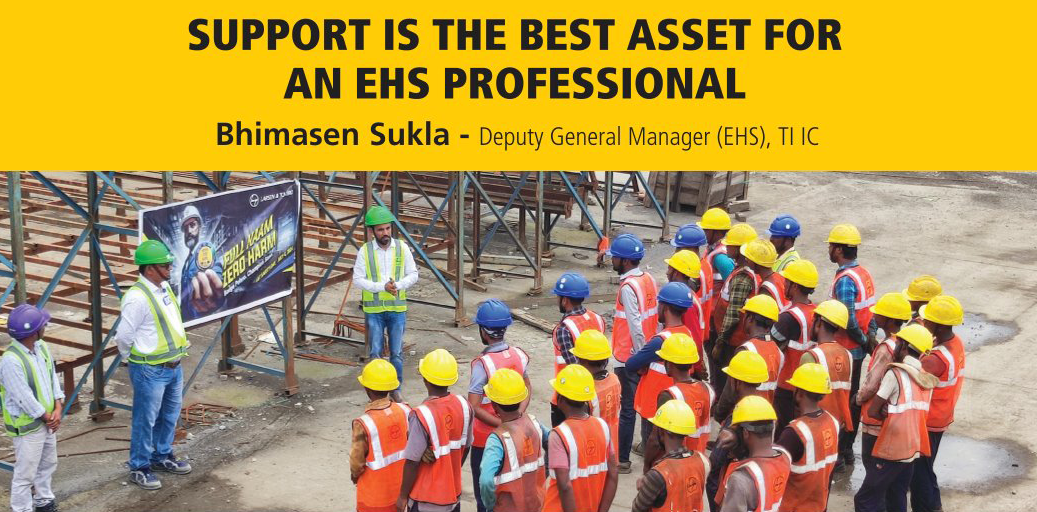

“My Project Director and seniors have always given me a free hand and welcome my suggestions on EHS matters; whenever I need help, they stand by me, and this support is the biggest asset for an EHS professional,” declares an emotional Bhimasen Sukla, who at WDFC EMP-14 is executing his first project with L&T, although he has joined with years of rich experience behind him.

Helping him in his arduous task of keeping everyone safe in a linear project of great size, is technology. “We have QR codes for all lifting equipment and pressure vessels, anti-collision devices and human sensors on all EOT cranes, implemented a CRO manual, use the SHIELD App for observations, permits, checklists, near-miss reporting, and AR & VR to train employees.” Bhimasen is delighted that because of their perfect coordination with DFCC/IR for traffic and power block, the site has not experienced a single electrical incident so far. The project has had no penalties either, thanks to their excellent relationship with DFCC.

“I have been conducting EHS quizzes on WhatsApp continuously for 2 years with monthly prizes and appreciation,” he shares, “and I travel to all corners to monitor the site. My regular yoga gives me stamina,” he smiles. “I am working hard to bring about attitudinal changes in site managers, engineers and supervisors for 100% utilization of digital platforms in EHS,” he promises.

Frequent changes in leadership have been one of his various challenges. “You need an understanding and patient approach to control the situation and convince people of your point of view,” he observes. The three BUs involved are coordinating well and the team has been complying with all legal requirements since the project is in the NCR zone and passes through three states. “Timely compliance and social relationships make the difference,” he avers. Going forward, he hopes to see QR codes system for all equipments across projects to check workers competency and adapting biometrics for all heavy equipments/plants.

Bhimasen is understandably ecstatic of the awards the project has won: the NSCI-Gold Award 2020, Prashansha Patra (thrice), 4 certificates of appreciation, the WSO Gold Award, Gold Medal from RoSPA after five consecutive RoSPA Golds, the client’s appreciation for successfully clocking 23 million safe manhours and successfully organizing the DFCC train trial run. “My write up was published in the National Safety Dairy and the National Safety Chronicle,” he says proudly, apart from being a guest speaker at various forums.

On the personal front, he is a native of Kendrapara, Odisha, and is married to Sailendri, a homemaker; they are blessed with a daughter, Sanskrita. He loves watching cricket too.

“In the construction industry, change is typically driven top down,” according to Dharamender Kumar Yadav, speaking about technology adoption at WDFC CTP14, his fifth project at L&T where he is currently Section In-charge. “To successfully implement at the project level, Project Managers and Construction Managers must actively promote and insist on the adoption of technology at every level.”

Dharamender and team monitor site progress using drones at frequent intervals, which helps the management visualize the real site issues and provide appropriate solutions. “This method is also used by the design team for better clarification to modify drawings as per the site conditions.”

Grateful for his seniors’ wholehearted support for his team’s digital initiatives, he says, “They provided the necessary approvals to procure all our digital devices and guided us to implement them.” To further improve project execution, Dharamender is keen for more enhanced digitalization in labour management.

At the CTP 1&2 Project, where he was stationed previously, Major Bridge 35 (MJB 35) was one of the most critical major structures, with a 100 m span and ~32 m vertical height. “I was tasked to complete the structure within a stringent timeframe,” he recalls. “I mobilized and efficiently utilized resources to ensure on-time delivery thanks to a comprehensive plan developed by our team that included all the critical activities. With a proactive approach, our competent team completed the bridge right on schedule,” he beams.

“L&T provides employees the opportunity to implement their vision if they are prepared to assume responsibility, meaning that if you have a clear vision or plan for a project or initiative, you will find the support to put that vision into action,” Dharamender says with evident pride. “Along with this freedom comes the expectation that you will take ownership of the outcomes and consequences of your decisions and actions, and I love how L&T encourages proactive leadership and accountability from its employees!” he adds shrewdly.

A native of Kohara, Kosli in Haryana, he is married to Kusumlata, who is a lecturer. They are blessed with a son, Divyam, and a daughter, Freya, whose birth is Dharamender’s most memorable moment. When he finds the time to relax, he enjoys listening to poetry, Rashmirathi in particular.

A native of Kohara, Kosli in Haryana, he is married to Kusumlata, who is a lecturer. They are blessed with a son, Divyam, and a daughter, Freya, whose birth is Dharamender’s most memorable moment. When he finds the time to relax, he enjoys listening to poetry, Rashmirathi in particular.

One of Raj Kumar Yadav’s major hurdles to introduce digital solutions was the refusal of vendors to install digital devices on their machines. “We had several meetings with them to explain the merits of digital implementation till they accepted,” he says with a punched fist. “We also created awareness among the operators & drivers about the importance of digital devices and how the safety devices protect them while operating their machines.”

Raj’s efforts have certainly succeeded. “First, we installed GPS systems in all the assets to track vehicle movement and utilization and later upgraded with fuel sensors (M/s Spotrack) to verify fuel consumption, productivity as well as fuel removal. Based on this report, we deduct from the running bill.” To monitor the HSD issue, Raj refers to RFIDs installed on the fuel dispensing unit to ensure proper and accurate fuel issuance.

To drive Safety at site, Raj reels off a long list of digital devices installed in vehicles including safe starters in soil compactors, reverse cameras in transit mixers & motor graders, delay starters in motor graders & wheel loaders and ASLI systems in hydraulic & Pick & Carry cranes. “All weighbridges have been converted from analog to digital load cells with CCTV cameras installed to avoid manipulation, both weighbridges and batching plants are connected to IOT, reports of which are available on EIP and all the batching & WMM plants have CCTV cameras to help the plant operator monitor all the plant operations from his cabin to avoid any incidents,” elaborates Raj.

A true digital native, Raj is keen to implement biometric attendance of all operators and drivers in linear projects, linked to the ignition circuits of their vehicles to ensure that only authorized operators/drivers operate them. “We would also like to initiate a QR code system in vehicles that stores all the RTO related documents including the operators’ licenses so that the docs can be easily scanned and viewed,” he shares, looking ahead.

Looking back, Raj began his journey with L&T at the DMRC CC27 project overseeing one underground station and P&M operation & maintenance, followed by a stint at the Kolkata Metro project before being transferred to his present assignment at the WDFC CTP-14 as P&M In-charge responsible for P&M operations across the project and overseeing I‑Girder erections.

On his home front, a native of Haryana, Raj’s better half is Bhagwati, a homemaker, and they are blessed with two children: daughter, Vanshika and son, Navleen. Watching and playing cricket gives him as much joy as he enjoyed erecting I‑Girders at his BR-87 project.

“Making technology easy to understand and use for people from all departments can encourage more people to use it,” remarks Jaishankar Batra wisely. Having just completed a decade at L&T, he reflects on the organization’s commitment to innovation and engineering excellence. “Being associated with a company that values innovation not just as a buzzword but as a core principle is truly inspiring!”

Currently at the WDFC CTP14 Project since May 2017, Jaishankar is leading the planning functions of structures and is responsible for coordination with the client, design team, and HQ for approvals, subcontractor management, costing, scheduling, and more. “We have transformed client experience by presenting the construction methodology in bridge 3D models generated through design software, to give the client a practical idea of how the project will look after completion,” he informs.

In April 2020, as a part of HCI IC’s bulk material optimization exercise, Jaishankar and team implemented ConEase, a concrete optimization tool. The produced concrete is despatched from the plant and once received at site, is updated digitally by the site engineer; the quality team then uses the automatic indent data for issue to stores, which helps in periodical reconciliation. “With live tracking of concrete and automatic reconciliation, we have reduced bulk material wastage and enhanced P&M productivity.”

Jaishankar is thankful to his seniors, peers, and subordinates for their full support in effectively implementing these digital initiatives, which include progress monitoring through TILOS and aerial surveys through drones. “These have helped our design team gain clearer insights into necessary modifications in drawings based on actual site conditions,” he notes gratefully. This was especially useful in the deep-cut section which includes 6 km where 9 structures were crossing the alignment. “We adopted the top-down construction method for easy construction, eliminating the challenge of mobilizing resources in deep areas and reducing several manhours,” he adds.

Jaishankar would like to see the concept of ‘Digital Stores’ implemented, especially in linear projects having multiple warehouse locations. “It will help us track stock availability and prevent reordering at one warehouse when the material might be available at another,” he notes.

At his first project in L&T, Saurabh Sharma is managing S&T Works at WDFC CTP14, where Apps such as Procube and SHEILD have helped organize & manage tasks, schedules, and resources more effectively. “Our project delivery timelines improved as also quality and safety,” he shares enthusiastically.”

At the CTP14 Project, electronic interlocking software had to be installed at all stations with train movement in the entire stretch. “To ensure no error in logic, we proposed a Factory Acceptance Test (FAT) that included a dummy simulation of the entire yard with four setups, enabling round-the-clock testing with 3–4 shifts daily, to meet our scheduled testing goals and ensured successful train movement under the signalling system by DFCCIL Station Masters,” Saurabh reveals.

There was limited client engineer presence on site during multiple activities; Saurabh and team facilitated material and ‘virtual’ site work inspections and sharing test results via MS Teams, which helped maintain effective communication throughout execution. “I believe that client focus on digitization can enhance technology adoption significantly,” he remarks, “and encourage involvement at all levels to align our efforts more effectively towards integrating technological advancements into our processes.”

Saurabh would love to see more digitalization in design submissions for client approval. “I think it is crucial in the current era, as it will reduce the impact of paper-based contractual submissions, which aligns with our sustainability goals to promote a more environmentally friendly documentation and approval process.”

Hailing from Hapur, Uttar Pradesh, Saurabh is married to Apporva, a homemaker, and they are blessed with a son, Shriyaan. “I enjoy gardening and reading fiction,” he says. “Given the pressure of early completion from the client, finding time for these can be challenging. However, I make it a point to indulge in my hobbies especially on Sundays.” His most memorable moments are his school holidays spent with the whole family in his village.

“Being an L&T‑ite fills me with pride as we contribute to progress across all fields,” Saurabh says with a gleam in his eyes as he signs off. “Ram Mandir, space missions, highways, rail networks, monuments, Parliament, and the ‘new’ India – we are there, everywhere!”

One of Gourav Bhattacharya’s most memorable moments was successfully completing the CRS of the Reasi – Sangaldan section and speed electric loco trial on 28 June 2024. “I felt on top of world as I watched an electric train passing on the Chenab Bridge, the world’s highest railway bridge,” he shares was great enthusiasm, highlighting a point in his journey with L&T that started in July 2013 as Graduate Engineer Trainee at the Valadai – Manaparai Railway Doubling project. Presently, GBC, as he loves to call himself, is Planning In-charge at the KRCL project taking care of its overall financial parameters, resource management, physical completion, and a lot more.

Although technology adoption has been robust at his project, GBC is candid about steps to drive it even more. “Ideally, multiple applications should be combined under a single umbrella, Apps should be lighter for smoother running even in low-spec mobile phones, and alternative methods should be avoided if already addressed by digital solutions. Easy-to-use interfaces and a small learning process will help too,” he says with conviction.

With 62 Rkm of his 72 Rkm project being tunnels, deploying laser-based surveillance of tunnels has hugely propelled their progress. To erect the drop tubes for the tunnels, they introduced an OHE Height-Stagger Gauge which when placed on the tracks immediately provides the angle of the track, height of the tunnel crown and other important parameters. “This has not only saved us a lot of time, but we could procure all the materials even before the tunnel was handed over to commence the ROCS work,” says GBC with a winning smile. Their implementation of MS project has significantly improved profitability and, “we have also implemented SharePoint for documentation of all project correspondences,” he adds.

He is full of praise for his Project Manager, Chandan Kumar, for his encouragement, support & guidance. “He has given us a free hand to implement any new ideas and technologies. At the same time, my team members have supported by providing their on-field experience and relevant data especially to implement the stagger gauge and ROCS work.”

GBC’s passions are playing cricket, listening to music especially while travelling, and cooking. “I try to cook at least one dish on Sundays & holidays,” he grins, much to the delight of his wife Poulami, a homemaker, and their 2‑year-old son, Reyansh. GBC is a proud L&T‑ite for being a part of the team that builds the largest, the longest, the most complex landmark projects across the globe.

He is already 6 projects old with L&T, time enough for Swapneswar Nayak to realize as a safety professional that driving safety at site is a shared responsibility; it is never about ‘me alone’ but always about ‘Us’, which is why he puts a premium on the support and guidance from his seniors & team members. “They have provided direction, vision, motivation, inspiration and helped to create an environment conducive for success by promoting communication and collaboration,” he shares meaningfully. Constructive feedback is critical to refine technical solutions and improve problem-solving abilities, he adds, “and by demonstrating strong technical skills, leadership qualities, and a passion for learning, we are setting the right example for our team to emulate and follow,” he avers.

Firm with his fundamentals, Swapneswar Nayak must bring all his EHS learning to play at his present assignment, the challenging UDMP–SRIN–BRML Rail Link Project at Jammu for KCRL. “Ensuring everyone’s safety is of utmost importance for us considering that we are executing in various challenging locations like landslide-prone areas, working at height on the world’s tallest railway Chenab Bridge, transporting men and material to work locations and working in 11 km long tunnels,” he shares grimly.

“Oh no, one EHS person is not sufficient to look after Safety and maintain all the EHS stuff in such a linear project,” he says, shaking his head vigorously. “What helps are our digital technologies,” he points out with a smile, “like the SHEILD Safety App. We have given access to our non-PS EHS staff to do all EHS related documentation.” Convinced that the Safety App has improved both safety & quality, Swapneswar Nayak shares some of their daily practices with it: “Pre-work checklists are filled by the Site Engineer, EHS observations are submitted after identifying unsafe acts and conditions and compliance reports submitted by the Site Engineer or Site In-charge within the agreed time frame.”

Looking ahead, he hopes for increased compatibility and interoperability, to ensure that the new technologies are compatible with existing systems and devices to reduce barriers to adoption. “Interoperability between different platforms and technologies allows users to integrate new solutions without completely overhauling their current set ups,” he states wisely. About L&T, he says, “Our company values are based on respect, integrity, and accountability, and I believe in them wholeheartedly.”

On his personal front, hailing from Rourkela, Odisha, Swapneswar Nayak is married to Saraswati, a homemaker, and they are blessed with son, Sohan. “My hobbies are playing cricket and exploring new places,” he signs off happily.

EVERY CHALLENGE IS AN OPPORTUNITY TO EXCEL

Souvik Das

Engineer (Elec), TI IC

At his present assignment at the Katra–Dharam Railway Electrification Project where he is Planning Engineer, Souvik has been facing challenges that he, with his team, have been facing head-on and skillfully overcoming. “Every challenge is an opportunity to excel,” he says with gravity, “like how we deployed a laser-based OHE Height & Stagger Gauge for smooth and quick measurement of parameters for the Drop Tube design when the tunnel cross sections for the drop tube design were unavailable.” Additionally, he mentions using MS Project with SharePoint for progress monitoring and delay analysis due to the difficulty of terrain and site access that were hindering productivity and project progress.

“With our project being a joint venture with Furrier & Frey India Limited, maintaining documentation was critical but accessing them was difficult due to corporate system protocols,” he says, pointing out another challenge. “We have adopted SharePoint to easily access documents for both L&T and F&F simultaneously, and by mapping them with MS Project, it supports us for analysis.”

While the mindset of people reluctant to adopt digital solutions is a huge negative, according to Souvik, it is necessary to adopt BIM or a similar digital solution to get site parameters as well as prepare as-built drawings.

“My seniors and team members have always supported my ideas to use the latest technology to improve work productivity and they have shown keen interest to understand and implement technology at the execution phase itself,” says Souvik with a sense of achievement. “My Project Manager, Chandan Kumar has also helped me to optimally utilize the digital solutions we have adopted at the project.”

Proud of being a part of a Company that is involved in nation-building, Souvik started his L&T association as a DET in 2018 at the Roha Verna Konkan Railway Electrification Project. “It was a big learning experience for me,” he recalls fondly, “being responsible for progress monitoring, material assessment, material procurement, non-schedule Items, variation approvals and claim management, client and subcontractor billing.” Presently, his responsibilities apart from his earlier ones include, job cost reports, EIP system works, site coordination, material management, drop tube design and procurement, and documentation.

A native of Bankura, West Bengal, India, Souvik’s better half is Arpita Paul, a homemaker, and his eclectic hobbies include playing the guitar, chess, cricket, dancing, writing, & travelling.

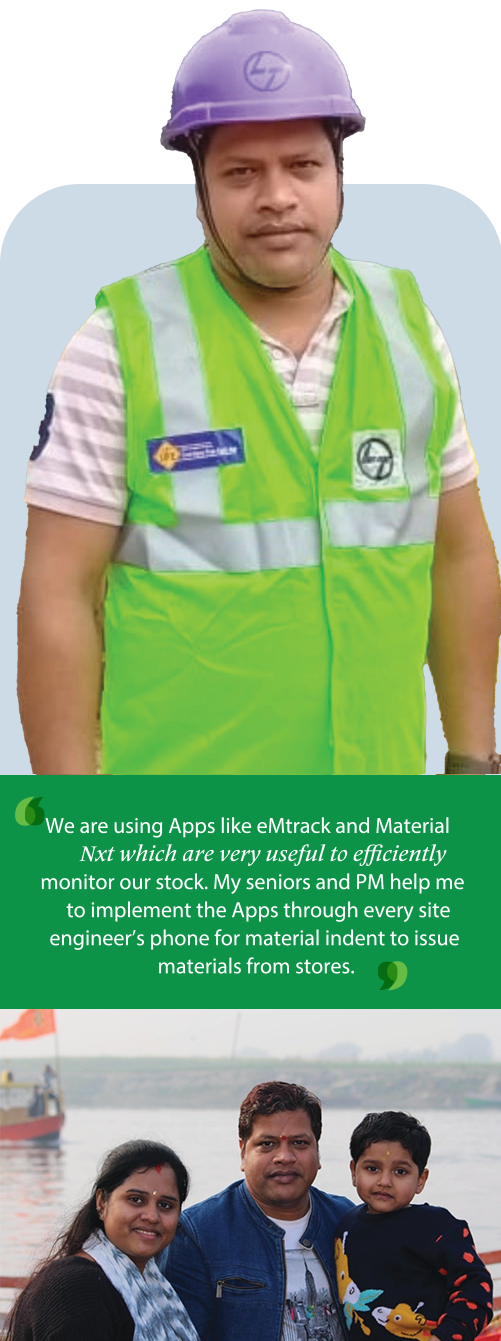

“L&T is a very systematic organization because I see that if someone is interested to work in his or her favourite field, then everyone, even the Project Manager, appreciates and recommends you to do your best in that sector,” shares Debasis Saran, with a broad smile reflecting his pride being with L&T. “This is also an organization that offers employees the opportunity to learn and as you learn, you will become more knowledgeable which is why I am proud to be a part of this great organization.” A lateral, Debasis has worked with other construction companies earlier and is presently at his first project with L&T at the Agra Metro, managing stores.

“In my previous organization, we were using the Bar Code system to issue indoor materials from stores which were linked with the software so that whenever we issued material, it would automatically deduct from the stock,” he recalls. “Here in L&T, we are using Apps like eMtrack and Material Nxt which are very useful to efficiently monitor our stock. My seniors and PM help me to implement the Apps through every site engineer’s phone for material indent to issue materials from stores,” he shares, obviously happy with the way things are moving.

Like several of his colleagues across projects, Debasis also feels that frequent training programmes for site engineers are essential to drive tech adoption at sites by educating them how to use the various Apps and EIP, and additionally making them aware of the many benefits of digitalization. In terms of introducing new solutions, he opines, “It would be great if we can develop one App for TMT Bars, linked with the BBS (Bar Bending Schedule), to enable us to issue the exact quantity from store and reuse the cut pieces from scrap.”

On his personal side, Debasis is from Cuttack, Odisha, and married to Samapika Subhadarsinee, a homemaker, and they are blessed with a son, Rudrasish Saran, who’s birth is his life’s most precious moment. When he is free, Debasis loves to sing.

ALWAYS FINDING NEW WAYS TO SERVE

Even though young Sufiyan Mehmood Shaikh is working at his first project, the Agra Metro, there are already several aspects about L&T that he is proud of starting with its commitment to innovation and continuous improvement. “I appreciate how we constantly strive to find better ways to serve our nation and our clients, improve our processes, and stay ahead in our industry. This forward-thinking approach not only keeps us competitive but also fosters a culture of learning and growth among our team members,” he states with great fervour. “It is inspiring to be part of an organization that embraces change as a means to achieve greater success.”

As Project Accountant, it is Sufiyan’s responsibility to get the numbers right and, as he points out, initially capturing & maintaining worker details manually was a tiresome task, but now with the implementation of the WISA App, his life has become so much easier. “WISA is really a smart move to improve efficiency and accuracy at project site for capturing and maintaining worker details has become so streamlined,” he grins.

His recognition as a Tech Champ is spot on because Sufiyan is busy thinking of introducing new technologies at site to further improve performance. “Yes, I am excited to introduce new technologies like ChatGPT in my daily tasks to boost productivity and streamline processes,” he nods, mentioning that the introduction of Alexa or a similar voice-assisted technology to handle company policies and related queries can be a great idea too. “It can streamline the process of getting information, especially from new employees or for those who seek quick answers.”

As he integrates himself into the L&T style of working, Sufiyan is learning the ropes fast thanks to the mentorship and guidance of his seniors. “They share their experiences, and offer advice on technical challenges, to help me guide through complex projects,” he says thankfully. He is grateful to his team members too for sharing their expertise in specific technologies or domains that help him to learn new skills and stay updated with industry trends. “Their constructive feedback about my work is helping me improve my technical abilities and problem-solving skills,” he smiles.

The city that never sleeps, Mumbai, is his native place. Sufiyan’s better half is Tasneem, a teacher by profession but not working presently, although her hands must be full looking after their son, Ayan, who’s birth is his life’s most wonderful moment. When free, Sufiyan loves to swim.

MAKING THE MOST OF HER ‘BIG’ OPPORTUNITY

Bhavika Sahu

Senior Engineer (Elect & Comm), TI IC

Just a year old having joined L&T as a GET in 2023, Bhavika Sahu is making the most of her ‘big’ opportunity at L&T, which, according to her, is unwavering in its commitment to innovation and excellence. “L&T is renowned to undertake and successfully execute some of the most challenging and complex projects across various sectors, and I am proud to be a part of such a wonderful company.”

Although still very new to the construction industry, Bhavika is still excited about her steep learning curve. “I have had the opportunity to get myself acquainted with the various departments of my project, Agra Metro, and currently I am looking after the Interface Department, coordinating with other stakeholders for the traction requirements.”

About technology adoption at site, Bhavika mentions the SHEILD and TORQ Apps. “SHEILD is a digital safety platform that helps plan our work properly by capturing and uploading leading and lagging indicators, based on which we can analyse root causes and take necessary safety precautions to minimize risk at our workplace,” she explains. “TORQ, on the other hand, is a Quality App to conduct quality audits efficiently by addressing and complying with any observations or non-conformities (NCs). TORQ automatically generates audit observations and streamlines the process, ensuring thorough and accurate reporting.”

On her part, Bhavika is contributing to the site’s efforts of driving digitalization by cooperating with those leading the initiatives, providing support in planning and resource allocation and maintaining open communication to report progress and address challenges. “Problem-solving involves identifying potential obstacles and working together to develop effective solutions,” she says seriously.

Getting all the tasks completed at the same time is very important for on-time project delivery, but when that does not happen, the system is stressed, leading to poor time management and reduced efficiency. “To address such issues, I have prioritized working on one thing at a time, setting clear goals and breaking information into smaller parts, which enhances understanding and creates a more productive working experience,” she says, revealing a methodical approach to project management in one so young.

While enhanced training and education programmes are imperative to improve skills and increase awareness about digital initiatives being deployed at site, Bhavika advocates the use of AI for project scheduling by creating AI-powered dashboards for real-time data.

A native of Raipur, Chhattisgarh, Bhavika is single and therefore finds lots of time to follow her hobbies of reading, singing, and playing. A lovely memory is when she participated in a Youth Parliament Competition in 2014 and a National-Level Karate Tournament in 2013.

ENTHUSIASTIC ABOUT LEARNING NEW TECHNOLOGIES

Having joined as a DET in 2018, Rajit Das is enthusiastic about learning new technologies that he can integrate into his daily tasks. Currently, working at the Agra Metro Electrification Project as Planning Engineer, taking care of subcontractor billing, procurement and Quality, his tech adoption curve has been steep.

At his first project, EDFC CP-204, Rajit started conducting virtual Factory Acceptance Tests (FATs) through MS Teams for different materials, both domestically and internationally, that significantly reduced travel time and costs. “I have upskilled myself through numerous online courses on the ATL Next and Percipio Apps and now I am familiar with the SHIELD App, which helps identify risks before executing work, to avoid accidents,” he points out.

At the Agra Metro project, he has learned about the Partner Portal, ILMS, TORQ, ‘L&T Eye’, and ‘L&T Earth’ portals. “I use the TORQ App to conduct quality audits, to effectively close observations and NCs, while audit reports are automatically circulated to the senior management via email, streamlining the quality audit process,” he shares. “I have created presentations on the Advance Shipment Note (ASN) and bill registration process for the Partner Portal and L&T Portal (EIP 4.0), that I have circulated to vendors. Additionally, I provide training on ASN and bill registration, guiding vendors on how to use the Partner Portal and complete ASN, bill registrations in the L&T portal.”

Delivering the Priority Section‑1 of Corridor‑1 within a remarkably short timeframe was a huge win for the team, especially considering that 90% of the materials were sourced internationally, requiring meticulous material planning and constant communication. “Apart from conducting FATs to save cost and time, we monitored vessel movements through online portals daily to ensure efficient management of logistics,” he smiles.

Rajit has a view on the shape of technology to come. “For example, technologies such as ChatGPT and Gemini are currently making a significant impact on our daily operations, and I think AI can help us a lot in our day-to-day work.” He opines that AI will boost productivity, automate routine tasks, analyse data for better insights and overall enhance time management, project coordination and execution.

Rajit hails from Arodihi, Bankata, Bankura, in West Bengal, is still single and loves to draw and explore finance & tech videos. A moment for him to savour was when he was able to take the financial responsibility for his sister’s wedding recently.